Ammonia (NH3), a compound consisting of nitrogen and hydrogen, is critical in various environmental and industrial applications. Detecting and monitoring ammonia is crucial because it greatly affects human health and the environment when present in high amounts.

Ammonia sensors are thus essential for accurately detecting ammonia presence in diverse environments – from refrigeration and industrial facilities to agriculture and livestock management. Using them, organizations are able to preserve human health and the environment while complying with stringent regulatory emission limits.

Applications of ammonia sensors

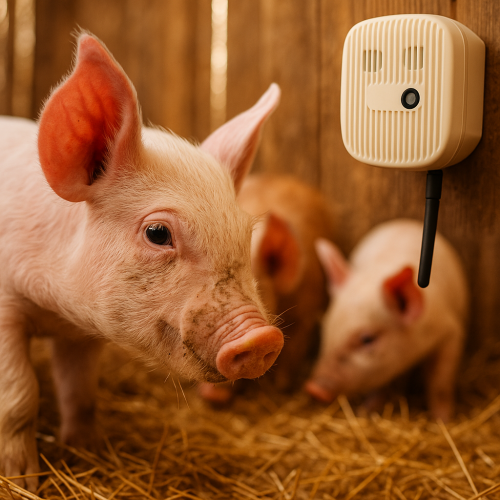

Agriculture and livestock industry

Ammonia is released into the atmosphere from volatile fertilizers and livestock activities, reacting with other chemicals to form secondary particulate matter. Measuring ammonia is challenging due to interference from other gases. It is also difficult because of the expensive standard technologies. Additionally, the short lifespan of electrochemical methods makes it even more challenging, despite recent improvements.

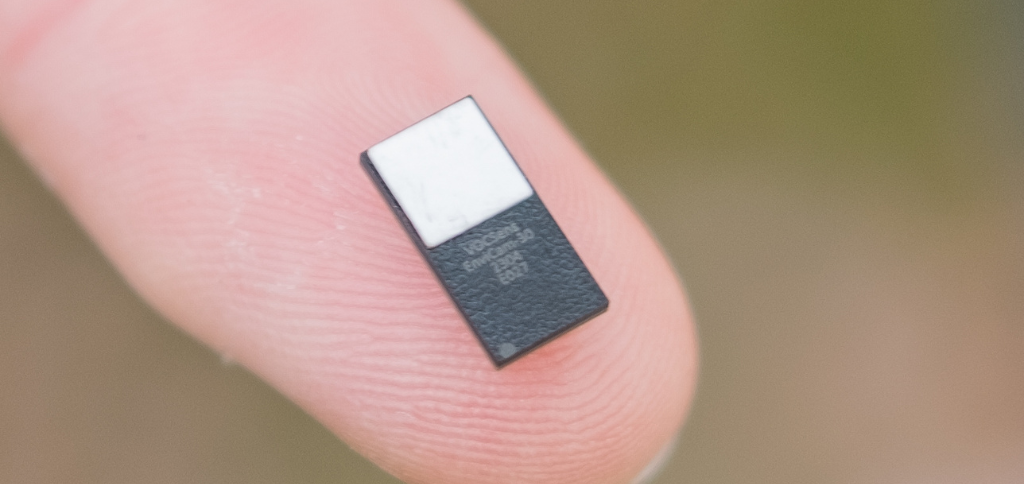

VOCSens’ EnviCam-3x-AFR, designed for the agri-food industry, addresses these challenges thanks to a microsensor technology combined with an AI-driven solution. Envicam-3x-AFR enables farmers to make immediate, data-driven decisions such as activating ventilation systems or initiating cleaning processes, in an economical way.

Refrigeration plants

Ammonia is commonly used as a cheap and efficient refrigerant in many industries, with minimal harm to the environment. Ammonia measurement sensors in these settings are crucial for monitoring air concentrations and detecting potential leaks.

Tank farms

Modern atmospheric ammonia storage tanks can hold up to thousands of tons of ammonia at plant sites and distribution terminals. Ensuring the safety of people and plants in these storage sites requires proper ammonia leak detection systems.

Ammonia (NH3) sensing technologies

There are multiple types of ammonia sensors on the market. Each operates on a unique principle, with its own advantages and (potential) limitations – that we have discussed in detail in an article dedicated to available gas sensing technologies.

Metal-Oxide (MOX) sensors

Metal-oxide sensors use variations in the electrical conductivity of semiconductor materials in the presence of gases like ammonia. They require a high-temperature surface for gas adsorption and electron exchange. This leads to important power consumption.

Nanomaterial and polymer-based sensors

These sensors function at room temperature and are resistant to humidity. They detect gases through changes in conduction properties, which are identified by resistance variations. These sensors can detect multiple gases simultaneously but may require self-calibration algorithms to account for environmental and aging-related drifts.

Non-dispersive infrared (NDIR) sensors

NDIR sensors measure gas concentrations by detecting differences in infrared light absorption by gas molecules. They are highly selective but can measure only one gas or gas family at a time, are bulky and require high power consumption.

Electrochemical ammonia sensors

Electrochemical ammonia sensors are widely used for their ability to measure low concentration levels and for their low power consumption. However, they are sensitive to high temperatures, have a limited lifespan and require sufficient knowledge of sensor chemistry for effective use.

Photoionization detectors (PID)

PIDs are precise in detecting low ammonia concentrations but are expensive, power-intensive and sensitive to humidity.

Catalytic bead sensors

These sensors measure combustible gases through thermal conductivity. They have a low response time and are easy to implement but have low selectivity and high-power consumption.

Choosing the right ammonia sensor

Selecting the best ammonia sensor depends on your specific requirements and on the intended application. In sectors like agriculture and livestock, where continuous monitoring of ammonia is challenging, innovative technologies like EnviCam-3x-AFR, a nanomaterial and polymer-based sensor, offer selective, reliable, affordable and real-time ammonia measurement solutions.

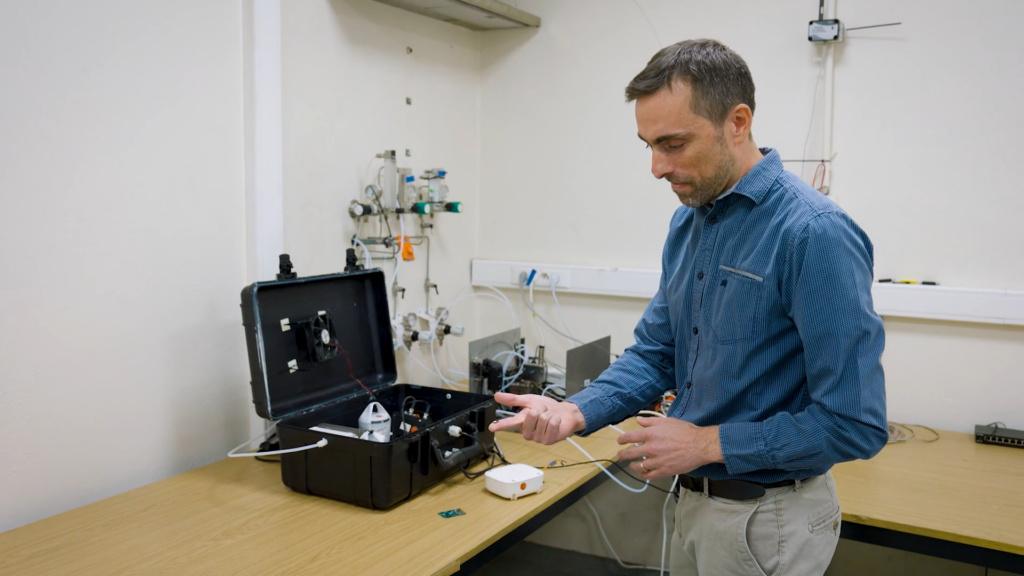

Case study

How ILVO, the Flemish regional research institute for the agricultural industry, has assisted industrial farmers in more accurately measuring ammonia emissions in poultry and pig farms.