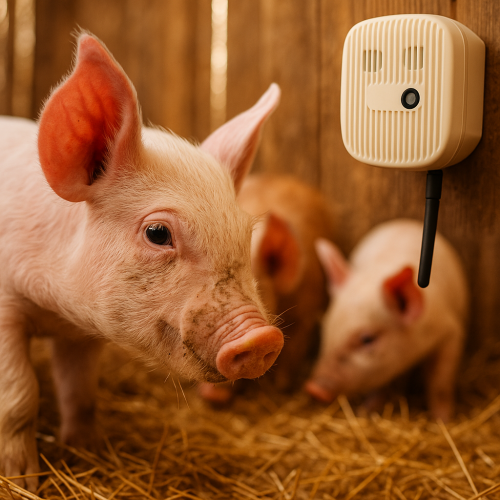

Gas sensing is an essential process across a myriad of industries, including the agri-food, (petro)chemicals and air quality management. However, accurately and reliably measuring gases at a reasonable cost presents numerous challenges. These challenges originate mainly from the limitations of current technologies and their inherent inability to provide absolute gas values, necessitating periodic calibration efforts.

In this article, we will explore the intricacies of gas detection and measurement, discuss current solutions and look ahead to the future of gas sensing.

The core challenges of gas sensing

Calibration

Calibration is crucial for the sensor’s ability to accurately detect and quantify gas concentrations in various environments. The process is fundamental in setting a baseline for the sensor’s measurements, which involves identifying the ‘zero point’ of the sensor in fresh air and determining its sensitivity curve based on known concentrations of the target gas.

Calibration can be broadly categorized into two types: zero (or fresh air) calibration and span calibration.

Zero calibration involves resetting the sensor baseline when it is in an environment free of the target gas. This process ensures that the sensor zero level is accurately set, which is essential for correct measurements.

On the other hand, span calibration is used to adjust the sensor sensitivity and response curve. This involves exposing the sensor to a known concentration of the target gas in a controlled environment, such as a stable with a constant presence of 20 ppm of ammonia (NH3), and then adjusting the sensor readings to match this known concentration.

However, challenges arise due to the need for frequent recalibrations, especially after the sensor has been turned off or exposed to significant changes in environmental conditions. This can lead to a shift in the sensor baseline and thus necessitates a fresh calibration to ensure continued accuracy.

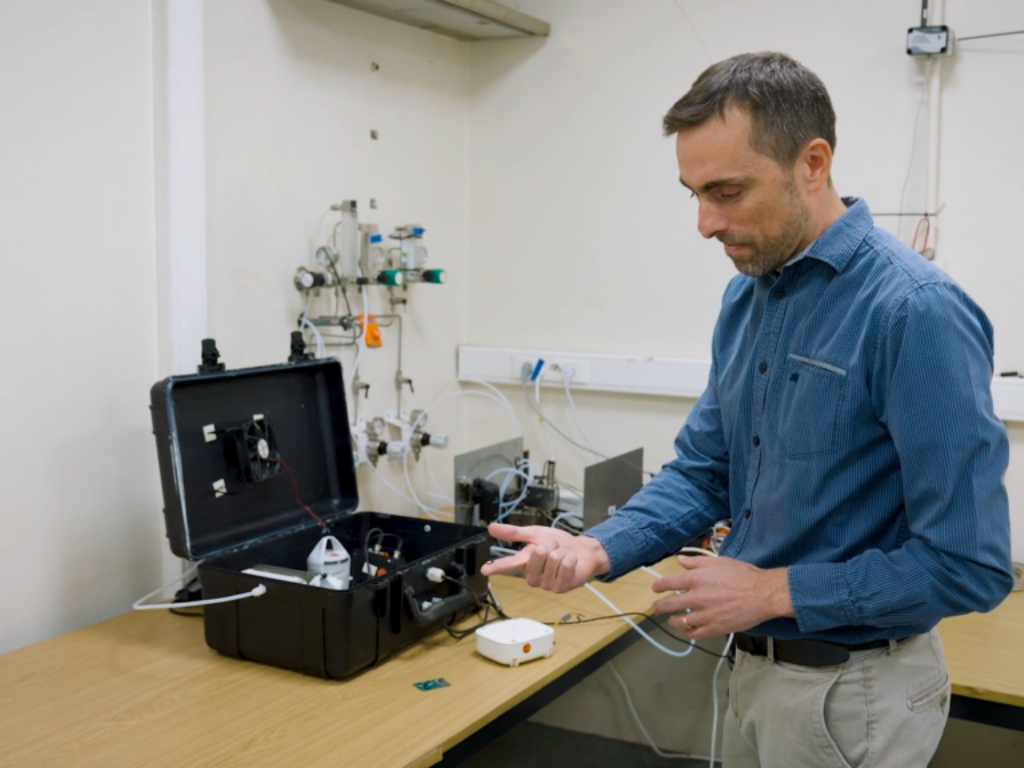

VOCSens’ technology aims to address these challenges by simplifying both zero and span calibration processes. Instead of undergoing a complex, multi-step calibration procedure, VOCSens allows users to specify the type of environment the sensor is operating in. The system and its data-driven algorithms then automatically adjust the calibration. This simplifies the process and ensures consistent accuracy across all measurements.

Accuracy

The accuracy of gas sensors refers to the tolerated range between the measured gas value and its actual concentration in the air. Factors such as temperature, humidity variations and cross-sensitivity can all contribute to inaccuracies. Cross-sensitivity occurs when non-targeted gases influence sensor readings. Achieving accuracy requires reliable calibration efforts and a deep understanding of sensor properties.

Selectivity

Gas sensors often exhibit better selectivity with specific target gas families. Detecting multiple gases simultaneously may require combining multiple solutions, which increases costs and complicates calibration and drift management.

VOCSens has identified a solution by integrating up to 16 sensitive materials on a single semiconductor. This choice opens the door to multi-gas measurement opportunities as other sensors are not inherently selective.

Material- and aging-related drifts

All sensors, regardless of type, experience drift due to aging or material degradation. Electrochemical cells, for example, become unusable when the electrolyte is fully consumed. Maintenance needs, heavily influenced by the measurement environment, can lead to significant costs and increase the total cost of ownership. Future models will rely on dynamic data and algorithms to estimate material properties over time and adjust gas data accordingly.

Present (and future) solutions in gas measurement

VOCSens is betting on EnviSoft, its software solution, to address the challenges of value variation and calibration. By leveraging an in-depth understanding of sensor chemistry and behavior, we are developing models for ‘self-calibration’ that consider both environmental data (temperature, humidity) and the sensor’s properties and aging. Furthermore, identifying chemical behavior patterns allows us to categorize each sensor by its measured properties. This paves the way for more reliable and cost-effective gas sensing technologies.

What’s ahead?

The future of gas sensing technology lies in the development of advanced materials and algorithms that can self-calibrate and adapt to aging. Ultimately, this will help to drastically reduce the need for external calibration and maintenance.

As we continue to improve our understanding of sensor behaviors and interactions with various gases, you can expect to see more robust, versatile and user-friendly gas sensing solutions.

The challenges of gas sensing are significant, but we are moving closer to overcoming these obstacles. By integrating sensitive materials and simplifying calibration processes through our self-calibration algorithms, we aim at improving the reliability, accuracy and cost-effectiveness of gas sensing technologies for a wide range of applications.